References

Explore the versatility and technical readiness of our biological methanation through our references. Our innovative technology excels in converting green hydrogen and CO2 into clean methane gas, making the technology a pivotal player in sustainable energy solutions. Dive into the world of biological methanation and discover its potential to reshape the future of energy.

Industrial scale methanation for P2X Solutions

P2X Solutions, a Finnish pioneer in green hydrogen and Power-to-X technology, is constructing Finland’s first industrial-scale green hydrogen production plant and methanation unit in Harjavalta. P2X Solutions produces green hydrogen completely emission-free through electrolysis of water using renewable energy sources.

The production capacity of green hydrogen is 20 MW. Construction at the site began in the fall of 2022 and the plant is scheduled to be in commercial use in 2025.

Methanation unit delivered by Q Power in P2X Solutions site Harjavalta

About the green hydrogen and methanation plant

P2X Solutions further processes part of the produced green hydrogen into renewable synthetic methane in the methanation facility delivered by Q Power. The production of hydrogen also generates heat and oxygen as byproducts, which can be utilized in industrial processes.

According to the schedule, the delivery and commissioning of the synthetic methane production plant to be built in Harjavalta will take place at the same time as the hydrogen production plant.

Read more about the methanation plant delivery

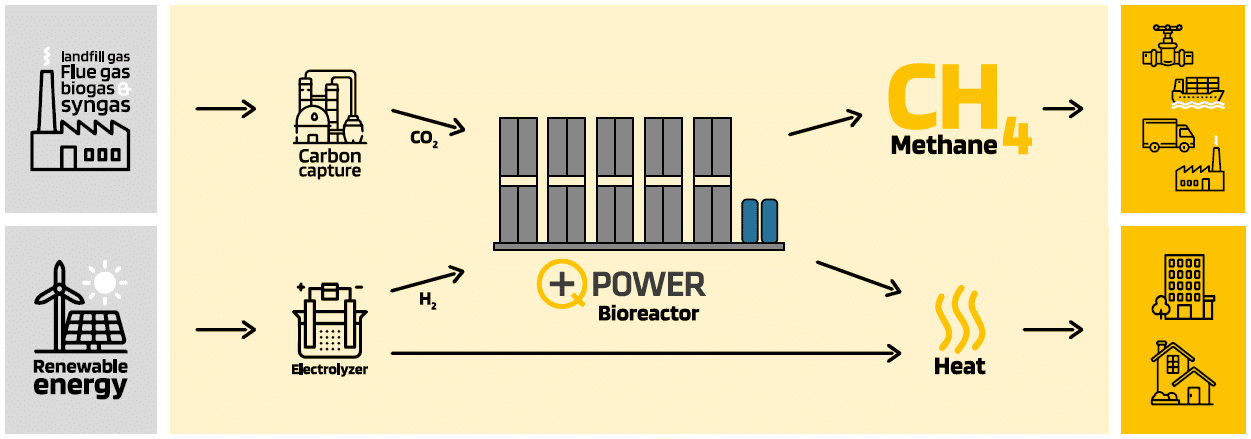

Methanation process

Landfillgas methanation in LSJH’s owned waste treatment center in Korvenmäki, Salo

Lounais-Suomen Jätehuolto Oy (LSJH) is a municipally owned waste treatment company. In Korvenmäki Salo, Finland it operates a waste management plant, where landfill gas is collected but due to the impurities, it can not be utilized.

The challenge and the goal

LSJH Korvenmäki waste treatment site

Landfills are a major contributor to greenhouse gas emissions, with landfill gas being a byproduct of waste decomposition that is rich in methane. In the Korvenmäki site, the goal was to utilize poor-quality landfill gas, that otherwise was unusable, in methane production. Q Power saw an opportunity to address this challenge by developing a technology to refine landfill gas into high-quality synthetic fuel.

The methanation on-site pilot in Korvenmäki waste treatment site

The production of synthetic methane was piloted in an on-site pilot, that Q Power has designed to validate the methanation process with the specific feed gas composition. Q Power provided a turn-key pilot project including a pilot unit, piloting process, data analysis and reporting. Methane was produced to traffic quality.

Results in landfill gas to methane piloting without pre-purification

All the targets for the project were met. Synthetic methane was successfully produced from landfill gas. Methane content was upgraded from 40-56% to over 90%. The biggest breakthrough was that no pre-purification was needed. The microbiological process effectively reduced the concentration of hydrogen sulfide, siloxanes, and other pollutants in landfill gas.

Biological methanation is a game changer

This pilot proves that Q Power’s landfill gas refinement technology is a game-changer in the field of sustainable synthetic gas production. By utilizing surplus gases as a resource, Q Power’s technology reduces the carbon footprint of industry, transportation, and landfills. Q Power helps to mitigate the effects of climate change and contributes to global energy security. Companies can partner with Q Power to reduce their carbon footprint, save on costs, achieve energy self-sufficiency, and positively impact the world.

Read more about landfill gas methanation

Views from our partners: Ambitious development plans at the Korvenmäki waste treatment center

Press release: Landfill gas successfully refined into traffic fuel at the Korvenmäki waste treatment centre in Salo, Finland

Download Reference brochure LSJH

Q Power’s microbiological methanation enabled Fortum’s pioneering pilot

Fortum, together with Q Power, has conducted a pilot at the Riihimäki waste incineration plant, the aim of which was to capture the carbon dioxide released from the waste incineration plant and use it as a raw material in the production of new high-quality materials, such as plastic.

Methanation on-site Piloting in Fortum waste incineration plant.

Image Copyright Fortum.

In Riihimäki’s pilot, carbon dioxide was recovered from the flue gases of the waste incineration plant, after which it was directed to Q Power’s bioreactors. By adding hydrogen produced with renewable energy to the microbiological process, the result was a carbon-neutral fuel, synthetic methane.

Methane holds immense potential as a raw material for downstream processing, including applications in the production of plastics and other valuable products. The advantage of Q Power’s technology is its scalability, toleration to impurities process stability and the best efficiency on the market (82%).

For CO2 recovery CarbonReUse’s chemical-free technology was used for this piloting project.

Purpose of on-site methanation piloting

To demonstrate CO2 capture from Fortum waste-to-energy plant flue gas

To demonstrate full synthetic methane production technical path.

What & How

The production of synthetic methane was piloted in an on-site pilot, that Q Power has designed to validate the methanation process with the specific input gas composition.

Q Power provided a turn-key pilot project including pilot unit, piloting operation, data analysis process and reporting.

Results

All the targets set for the piloting project were met. Methanation from the flue gas was successful. Utilization of flue gases in Riihimäki WtE for CCU and renewable methane production is possible with biological methanation.

Read more about Fortum and Q Powers co-operation in piloting

Q Power’s microbiological methanation enables Fortum’s pioneering pilot

The worlds smallest methanation plant

We are often asked how scalable Q Power’s solution is. We usually say that our technology scales to hundreds of megawatts, but scaling is also possible in the other direction. In this example, for a very small demonstration class.

In 2021 Q Power, Wärtsilä and Soletair Power joined forces, turned indoor air into fuel, which was used to operate the coffee machine. This demonstration unit was presented in Dubai World Expo.

Together we set up a demo plant producing synthetic methane from electrolysis hydrogen and carbon dioxide capture from indoor air. Q Power designed and implemented an automated and remote-controlled biomethanation unit for the demonstration, while Soletair Power completed the carbon capturing technology.

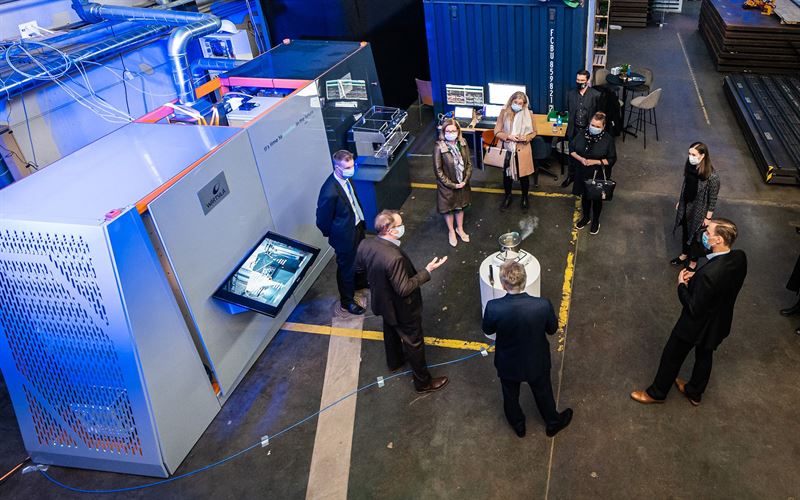

Prime minister Sanna Marin and her party visiting the worlds smallest eMethane plant 2021 in the Soletair facility .

Implementing the technology safe and stable at a small scale and in the environment surrounded by people required special attention to, for instance, automation of the system. Careful selection of measurement instruments and actuators combined with a thought-out automation design ensure a safe and stable end result.

During the demonstration project, we managed to implement a fully automated small-scale methanation plant that fulfills all gas safety standards. Maintenance of the plant is simple enough for anyone with basic training to carry out. This is certainly a project and end result that we at Q Power are proud of.

Keravan Energia, Flue Gas in its own heat and energy production

Keravan Energia is a modern energy company whose history dates back to 1906. Keravan Energia emphasizes renewable and CO2-free energy in its selection: in its own production, the company mainly uses domestic renewable wood fuel. The company has already reduced its CO2 emissions by 88 percent since 2010.

Methanation on-site Piloting in Kerava Energy’s waste incineration plant.

Q Power and Keravan Energia conducted a pilot for demonstrating the usage of flue gas in synthetic methane production.

Purpose of piloting

To demonstrate CO2 capture and utilization from district heating bioenergy plants’ flue gases.

Feasibility study for fully functional synthetic methane production plant technical path and economical feasibility. Considering also excess heat utilization.

What & How

The production of synthetic methane was piloted in an on-site pilot, that Q Power has designed to validate the methanation process with the specific input gas composition. Methane was produced to traffic quality.

Q Power provided a turn-key pilot project including pilot unit, piloting operation, data analysis process and reporting.

Results

All the targets for the project were met. Synthetic methane was successfully produced from carbon dioxide recovered from the flue gases of the biopower plant and from hydrogen produced with carbon-neutral electricity.

Bioethanol CO2 sidestream methanation pilot, Vantaa, Finland

In 2019, Q Power and Nordic energy company ST1 conducted a successful pilot methanating the CO2 side stream from a bioethanol production process. Findings:

- Methanation process is operational and efficient in an industrial environment.

- High-concentration CO2 side streams can be utilized as such.

- Residual concentrations of ethanol in the gas stream are not a problem.

Qvidja R&D center, Parainen, Finland

Q Power has designed and implemented a versatile R&D environment at the Qvidja Manor in Parainen, Finland. The site includes a methanation plant, gasification plant, biogas plant, gas storages, solar power plant, biogas filling station, and micro-CHP plant. Q Power can utilize the site in developing various novel solutions for customers.

More details

For additional information, please be in touch with

Director of Sales Sami Lakio

firstname.lastname (a) qpower.fi

+358 40 588 2728