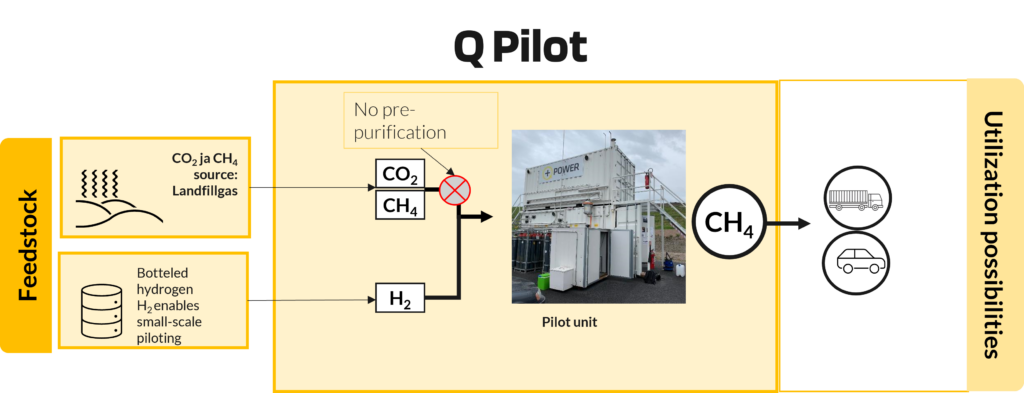

We are often asked how clean the gas containing carbon dioxide fed into Q Power’s reactor must be. The short answer is that the microbes in Q Power’s bioreactor tolerate impurities extremely well. We have confirmed this in practical pilot tests together with our customers. We have successfully managed to refine landfill gas into high-quality synthetic methane, thus more than double the amount of methane obtained from landfill gas, and all this without pre-purification.

Landfills are a significant source of methane emissions and carbon dioxide, both potent greenhouse gases that contribute to climate change. However, we are turning this problem into an opportunity with our innovative methanation technology. Landfill gas is a natural byproduct of the decomposition of organic waste under anaerobic conditions. It mainly consists of methane and carbon dioxide, but it can also contain small amounts of other gases such as nitrogen, oxygen, sulfides, etc., depending on the landfill waste and microbiota. Refining landfill gas into renewable fuel is generally challenging due to the presence of impurities in the gas, such as siloxanes and hydrogen sulfide. These impurities often prevent or at least make it difficult to utilize landfill gas.

There have not been many methods available on the market that can refine low-quality landfill gas into high-quality methane usable for traffic, and no methods at all that can utilize both methane and carbon dioxide from landfill gas. We have good news: Q Power’s biological methanation method has been proven to process landfill gas with impurities into a high-quality renewable fuel, even without pre-purification.

Our methanation process utilizes the carbon dioxide in landfill gas as a feedstock to produce renewable methane, which can be used for example to power homes, businesses, and vehicles. Thus, typically plenty of impurities containing landfill gas is simultaneously upgraded and purified during the treatment.

A breakthrough in utilizing landfill gas as a source for renewable energy

Q Power and Lounais-Suomen Jätehuolto conducted a collaborative pilot project to convert landfill gas into high-quality biomethane, the aim of the pilot was to use both methane and carbon dioxide from the landfill gas. The hypothesis for the piloting was, that the gas needs to be cleaned and pre-treated before the methanation process. But during the piloting, this was proven wrong and no pre-purification was needed.

The results of the pilot project were excellent: in addition to methane production, the microbiological process effectively reduced the concentration of hydrogen sulfide, siloxanes, and other pollutants in the landfill gas. In other words, Q Power’s technology not only tolerates pollutants well, but the process also acted as a clean-up process for landfill gas, with no pre-treatment required. This is a breakthrough in the utilization of landfill gas in the production of renewable energy. This is great news for the utilization of gases that contain impurities in general.

During the measurement periods, the methane content of the landfill gas was on average 40–56%, the carbon dioxide content 27–36%, the oxygen content 0–2%, and the hydrogen sulphide content over 5000 ppm. The average siloxane content of the landfill gas was 1.14 mg/m3 and the limonene content was 103.6 mg/m3. The microbiological methanation process increased the methane content of the gas to over 90% by volume. The amount of methane was increased by adding hydrogen to carbon dioxide. In addition, the gas was purified, as most of the hydrogen sulphides were removed in the process, as well as most of the siloxanes and limonenes.

– The joint pilot with Q Power went well and the results of the testing were promising from our point of view. The Q Power’s technology makes it possible to use landfill gas significantly more efficiently than previous solutions, says Teemu Jutila, development director of Southwest Finland Waste Management (Lounais-Suomen Jätehuolto)

Piloting is an important step when defining the need and way of treating impurities in landfill gas.

– The composition of landfill gas varies depending on the location, type of waste, and microbiology on the site. The pilot phase is important in determining the methanation process for a specific landfill. We were happily surprised by the process’s ability to tolerate and remove impurities, Q Power’s product development director Anni Alitalo reflects on the results of the pilot phase and continues – All in all, the result was significant and ground-breaking for the waste treatment sector.

Worldwide benefits for the climate and energy self-sufficiency

On a global scale, there is huge potential for recycling the gases generated in waste treatment, whether it’s from landfills or burning waste. Waste processing produces methane and carbon dioxide, which are greenhouse gases when released into the atmosphere. Combined with hydrogen, the collection and recycling of these gases into renewable methane offer the opportunity to use local renewable energy instead of fossil fuels. This concretely reduces climate emissions.

The landfill gas pilot with Lounais-Suomen Jätehuolto was a real breakthrough in reducing the climate impacts of municipal waste management because, in addition to methane production, the microbes in our bioreactor effectively reduced the concentration of hydrogen sulfide and other impurities in landfill gas. Q Power’s technology offers great opportunities to reduce climate emissions worldwide. By producing synthetic methane, both carbon dioxide and methane can be utilized as raw materials for renewable energy—even in those waste treatment plants where it was not possible before. As we have promised, we deliver concrete solutions to combat climate change.

Steps to turning landfill gas into synthetic fuel

As stated earlier, the gas compositions of different waste treatment plants differ from each other, as the quality of the gas depends on the waste and the age and microbiome of the landfill. Therefore impurities also vary from landfill to landfill and thus gas testing, piloting, and feasibility studies are important. That way we can define precisely the processing methods for the reuse of landfill gas. Piloting and surveying are also useful in calculating the investment of a possible methanation plant.

The LSJH project consisted of two phases, a pilot phase, and a feasibility study and calculations.

– Piloting and the feasibility study and calculations made with Q Power enable the project to continue. Based on them, we can start planning a full-scale methanation plant. The funding for the follow-up project has been applied from the Finnish Ministry of Labor and Economy. We hope that the cooperation with Q Power will continue, Teemu Jutila states.

The first steps from landfill gas to renewable fuel

- Preliminary study of the concept and piloting

- Piloting

- Feasibility study and calculations

We at Q Power help you to turn your carbon dioxide emissions into a valuable source of energy. During more than 10 years of research and development, we at have developed unique technologies that enable the efficient production of carbon-neutral synthetic fuels. Our methanation solutions make it possible to reduce emissions and replace fossil fuels with renewable alternatives.

If you are interested in discussing how you could benefit from Q Power’s technologies, please contact our sales team:

Sami Lakio

sami.lakio@qpower.fi

+358 40 588 2728

and

Sara Kesäläinen

sara.kesalainen@qpower.fi

+358 44 314 1942