During over 10 years of R&D, Q Power has developed unique technologies to enable the efficient production of renewable synthetic fuels. Our bio-based technologies enable our customers to store renewable power and replace fossil fuels, helping society in edging closer to a net-zero carbon future.

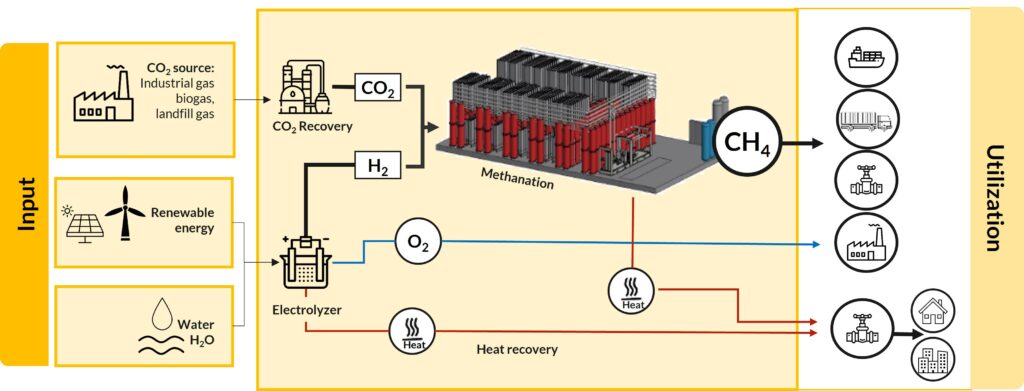

Q Power provides customers with the most efficient methanation technology on the market. Our biocatalytic methanation process utilizes microbes originally isolated from a Finnish marshland. Microbes produce renewable methane (CH4) from hydrogen (H2) and carbon dioxide (CO2) in our unique bioreactors. Our methanation technology is the most efficient currently on the market: the process efficiency of methanation is 82 %. The modular Q Power methanation technology’s scalability is almost limitless from 50 kW solutions to the range of 150 MW+ and even higher. Our scalability will meet your needs. Are you interested in methanation? Read more about our services or contact us.

Methane (CH4) is a simple hydrocarbon. Q Power has developed and honed a biocatalytic technology for the production of synthetic methane, chemically identical to the main component of natural gas. Methane is a versatile fuel with an extensive distribution and end-use infrastructure.

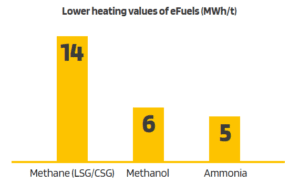

Our of all hydrocarbons, methane has the highest energy density per carbon atom, and therefore releases the least amount of carbon dioxide per unit of energy at combustion.

Methane can be used to heat homes, to power industry or to drive a truck or personal vehicle. Synthetic methane can be used on the site of production or injected into the existing natural gas distribution network. Natural gas networks also act as large-scale energy storages.

Synthetic methane is a sustainable substitute for fossil fuels, as well as a more attractive choice than other renewable fuels.

Methane is produced by reacting carbon dioxide and hydrogen in the Sabatier reaction: CO2 + 4H2 → CH4 + 2H2O. The reaction can be catalyzed in two alternative ways: either biologically and at low temperatures, or high temperatures and pressures and with metal catalysts. Our technology is based on biological conversion.

In our methanation process, CO2 is used as an input rather than discharging it into the atmosphere. The unique Q Power reactor design enables a highly efficient gas transfer and biological efficiency without the use of pressurizing or mixing.

Our process is both energy and cost-efficient, as the bioreactor does not require mixing, pressurizing or constant fluid pumping. The temperature of the process is only around 50 to 70 °C (120 to 160 °F), while catalyst technologies require a temperature of several hundred degrees. There is also no need for constant laboratory surveillance of the process. A full 82 % of the energy stored in hydrogen inputs is transformed into methane in our reactor.

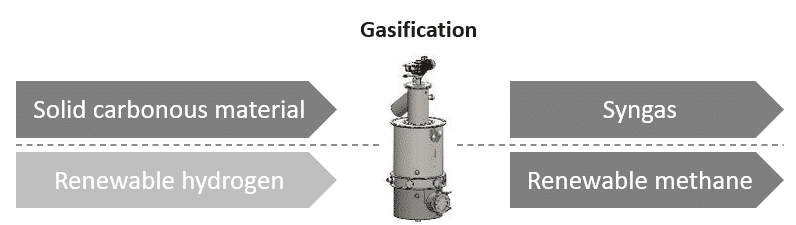

Gasification turns biomass or any other carbonous material into synthesis gas (syngas, product gas), a mixture of carbon monoxide (CO), hydrogen (H2) and carbon dioxide (CO2). Gasification occurs by reacting organic material at high temperatures (>700 °C), without combustion and with an optimized amount of oxygen.

If syngas is to be utilized in biomethane production, the gas produced needs to be tar-free. Our unique oxygen-enriched gasifier produces highly pure, tar-free syngas. A high operation temperature (>1000 °C) also ensures an efficient decomposition of other harmful substances.

Syngas created in the gasifier can either be used as such, or upgraded into renewable methane with our biomethanation technology.

While syngas is a valuable fuel in itself, biomethane has a far wider range of applications and is suitable for use in the existing natural gas infrastructure.

Certain micro-organisms are capable of performing a water-gas shift reaction (CO + H2O ⇌ CO2 + H2) under anaerobic conditions at an ambient temperature and pressure. Q Power has extracted a culture of such organisms and uses them in a patented bio-based syngas upgrading technology. The CO2 and H2 created are fed into our biomethanation process to create synthetic methane (CH4 ).