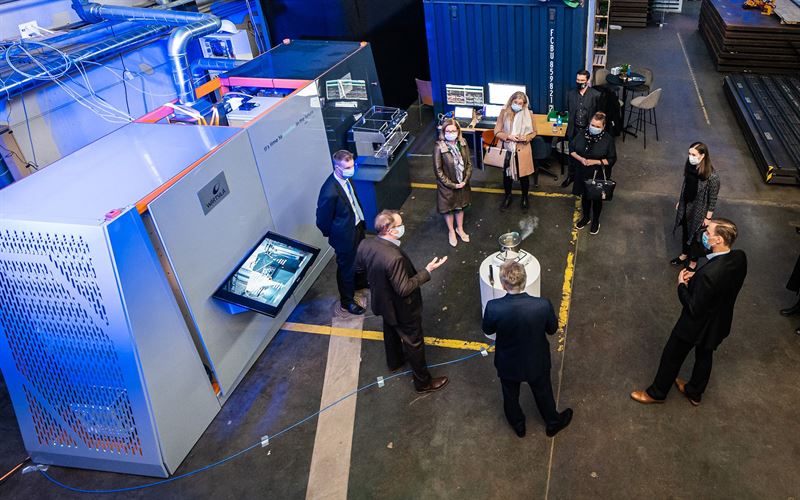

In September 2019, Q Power and Wärtsilä signed a strategic cooperation agreement related to the development of renewable synthetic fuels. Cooperation of the two forward-facing companied has concretely materialized for the first time as a Power-to-X demonstration project.

Wärtsilä and Q Power have, together with another Finnish startup called Soletair Power, implemented a demo plant producing synthetic methane from electrolysis hydrogen and carbon dioxide capture from indoor air. Q Power has designed and implemented an automated and remote-controlled biomethanation unit for the demonstration, while Soletair Power has completed the carbon capturing technology.

The concept of the biomethanation lies at the heart of the specialty knowledge of Q Power. The core of the process is our patented, tried and tested biological reactor technology. However, the scale of the device is far smaller than Q Power biomethanation units typically are.

Implementing the technology at a small scale safely and stably required special attention to, for instance, automation of the system. Stable operation of the biological process at a small scale is an interesting question in it’s own right, as the impact of external conditions to the process is heightened at smaller scales.

We have combined our extensive expertise in biological process management to strong competence in process technical and automation desing. Careful selections of measurement instruments and actuators combined with a thought-out automation design ensure a safe and stable end result.

During the demonstration project, we have managed to implement a fully automated small-scale methanation plant that fulfills all gas safety standards. Maintenance of the plant is simple enough for anyone with basic training to carry out. This is certainly a project and end result that we at Q Power are proud of.

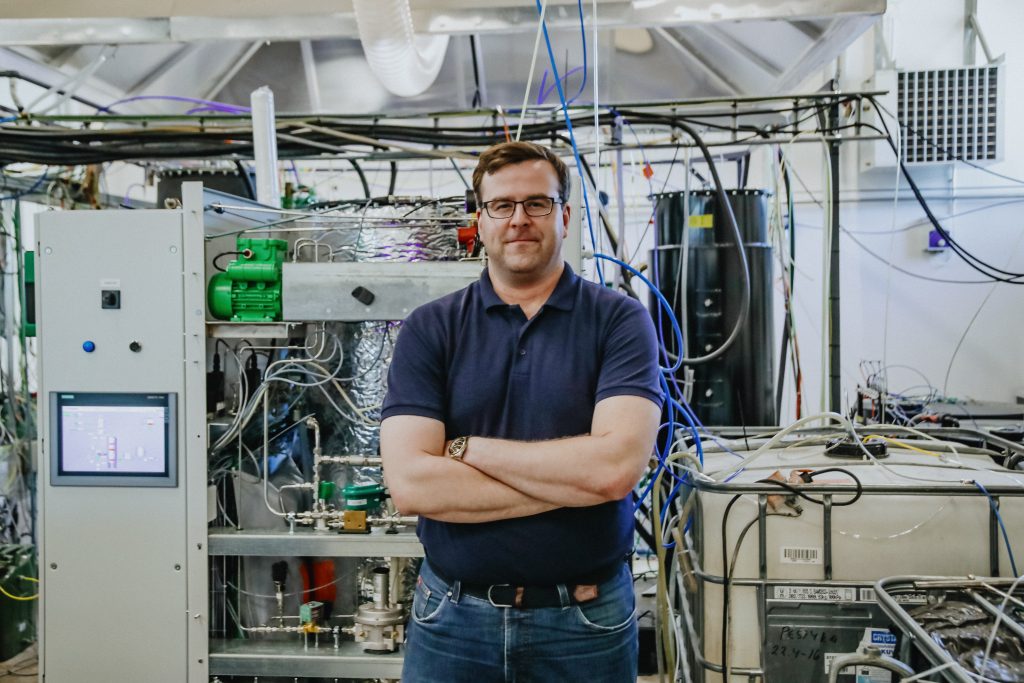

Marko Niskanen

CTO

+358 50 357 5363

firstname.lastname@qpower.fi